Ultimate Checklist for Choosing the Best Junction Box with Industry Insights and Data

In the ever-evolving landscape of electrical components, the Junction Box stands out as a critical element in ensuring safety and reliability in installations. According to a recent market analysis by Research and Markets, the global junction box market is projected to grow at a CAGR of 5.2% from 2021 to 2026, driven by the increasing demand for power distribution and renewable energy solutions. With a plethora of manufacturers claiming to provide top-tier junction boxes, it becomes imperative for buyers and engineers to adopt a strategic approach when selecting the right product. This checklist aims to guide stakeholders through the essential criteria for choosing a high-quality junction box, leveraging industry insights and the latest data to make informed decisions that align with safety standards and operational efficiency.

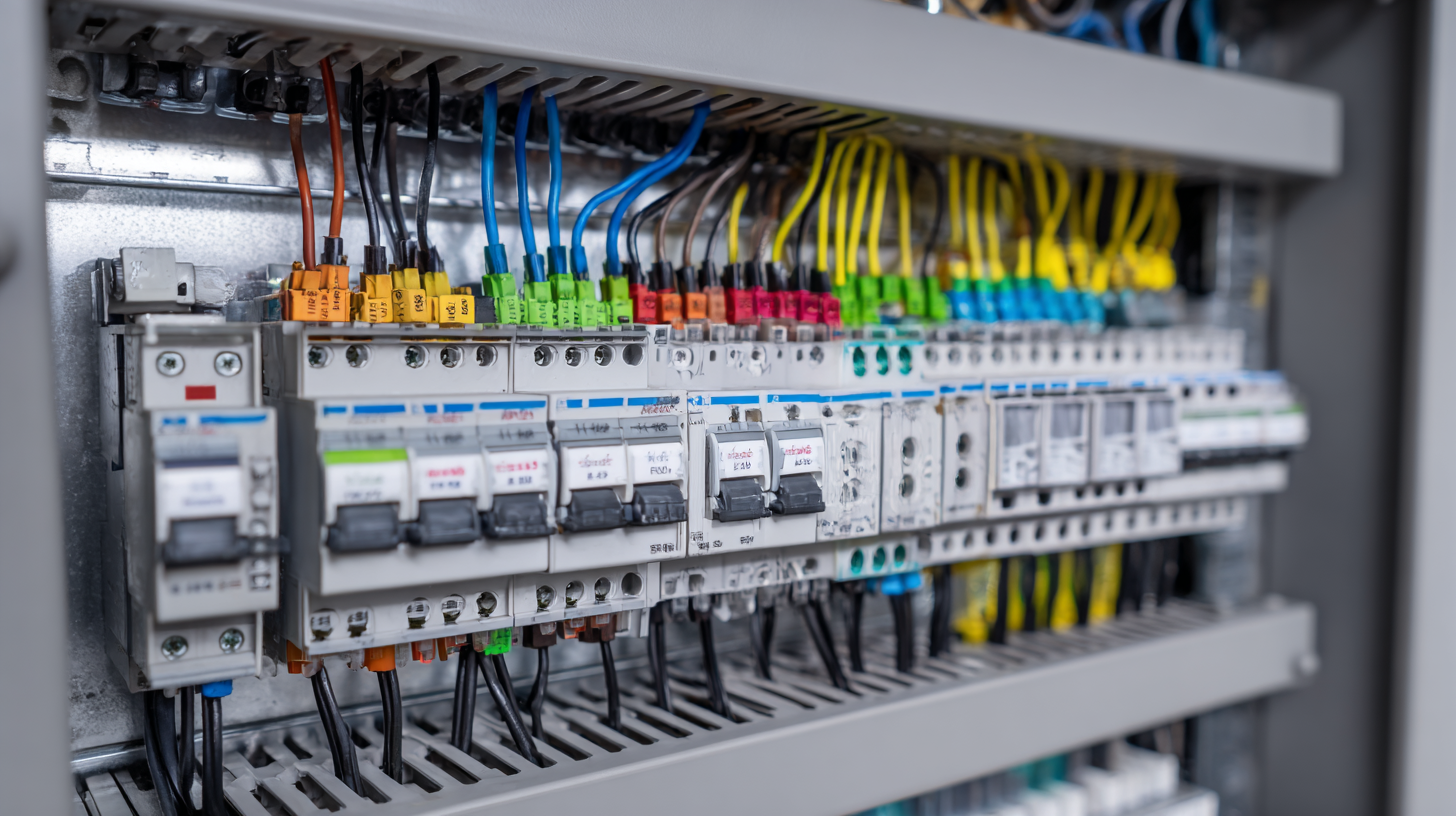

Top Factors to Consider When Selecting a Junction Box Supplier Based on Industry Standards

When selecting a junction box supplier, several key factors based on industry standards should guide your decision-making process. First and foremost, ensure that the supplier adheres to relevant certifications and regulations. Look for compliance with standards such as UL, CE, or IEC, which guarantee that the junction boxes meet safety and performance benchmarks. A supplier that maintains these certifications demonstrates a commitment to quality and reliability, ensuring that their products can withstand challenging conditions and maintain performance over time.

Another crucial aspect to consider is the range of materials and designs offered by the supplier. Different applications may require specific materials, such as polycarbonate, fiberglass, or metal, depending on environmental factors like moisture, temperature, and chemical exposure. A reputable supplier will provide a variety of options tailored to your needs, ensuring that you can find the right junction box for your specific application. Additionally, consider the supplier's experience in the industry, as established companies often have valuable insights and a track record of successful partnerships. This experience can lead to better support, quicker problem resolution, and overall peace of mind when sourcing junction boxes.

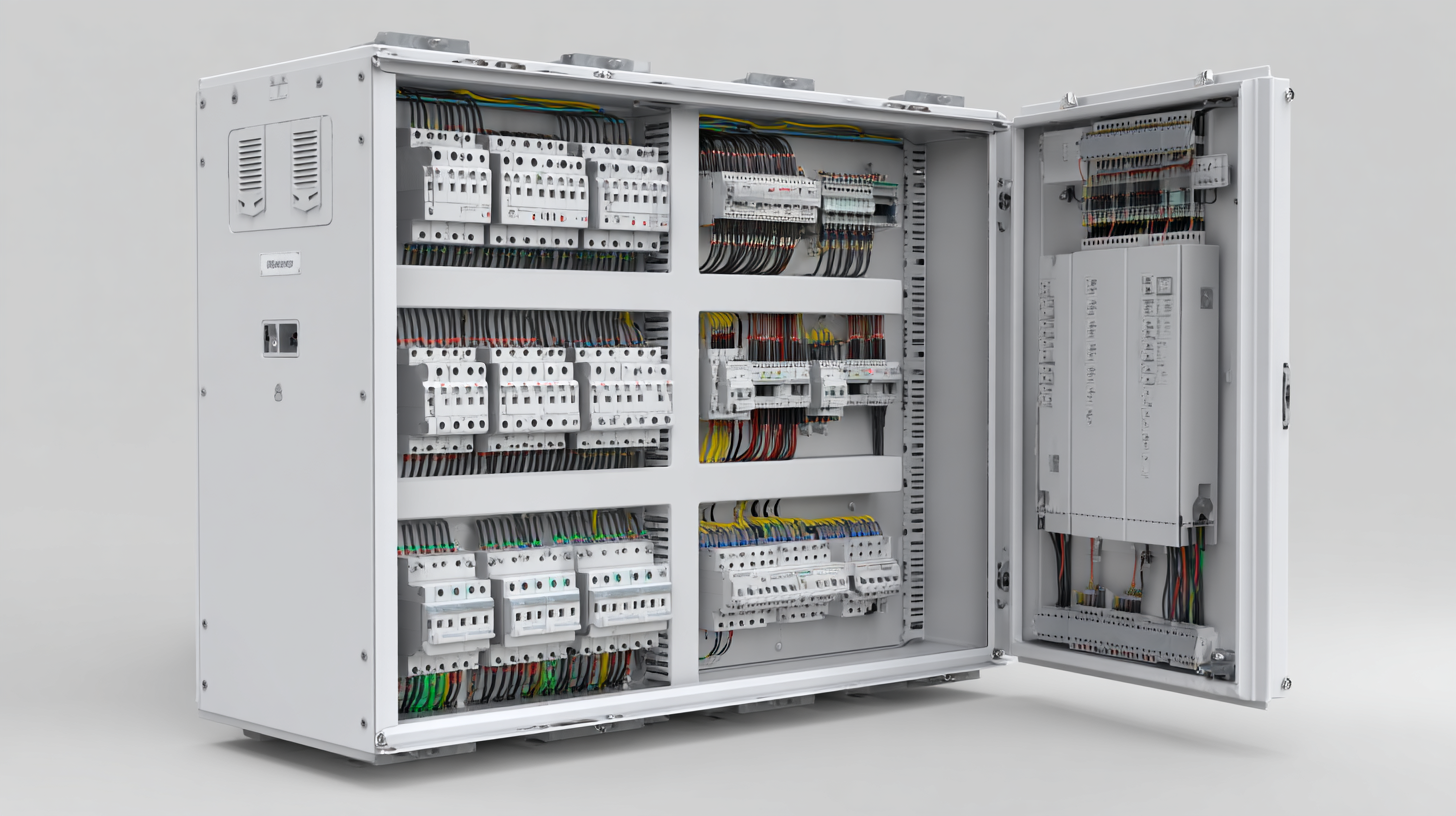

Key Materials and Certifications to Seek in High-Quality Junction Boxes

When selecting the best junction box, understanding the key materials and certifications is essential to ensure quality and safety. High-quality junction boxes are often made from materials like polycarbonate, fiberglass, or high-temperature nylon, which provide superior durability and resistance to environmental factors.

These materials can withstand moisture, corrosive substances, and extreme temperatures, making them ideal for a range of applications.

Tip: Always look for junction boxes that come with UL (Underwriters Laboratories) or CE certification. These certifications indicate that the product has been tested for safety and performance, meeting specific industry standards. Such boxes are particularly reliable in electrical applications, ensuring that they won't compromise the integrity of your connections.

Another factor to consider is the ingress protection (IP) rating of the junction box, which defines its resistance to dust and water. Higher IP ratings—such as IP65 or IP67—indicate that the junction box can protect against potent water jets and immersion in water, respectively. Choosing a box with a suitable IP rating aligns with the environmental conditions it will face.

Tip: Consider the installation environment carefully. For outdoor applications, opt for weather-resistant junction boxes with UV stabilization features to prevent degradation from sunlight exposure, ensuring that your installations remain safe and functional over time.

Exploring Industry Trends: The Growing Demand for Smart Junction Boxes

The demand for smart junction boxes is surging as the industry embraces advancements in connectivity and automation. According to a recent report by MarketsandMarkets, the smart junction box market is expected to grow from $1.2 billion in 2022 to $2.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 16.5%. This growth is largely driven by the rising need for efficient energy management systems and the increase in renewable energy installations, which necessitate advanced junction solutions for optimal performance.

Additionally, the integration of Internet of Things (IoT) technologies into electrical infrastructure is transforming traditional junction boxes into smart devices capable of real-time monitoring and diagnostics. A report from ResearchAndMarkets highlights that the adoption of IoT in electrical systems is projected to escalate by 25% annually, propelling the demand for smart junction boxes that can provide data-driven insights and enhance operational efficiency. Industries are recognizing the value of these innovative products, not only for their ability to improve safety and reliability but also for their potential to lower operational costs through predictive maintenance and energy optimization.

Market Analysis of Smart Junction Boxes (2023)

This bar chart illustrates the increasing market demand for smart junction boxes over the years from 2019 to 2023, indicating a significant trend towards the adoption of smart technologies in electrical solutions.

Data Insights: Comparing Price and Performance of Leading Junction Box Brands

When selecting the best junction box, understanding the price and performance dynamics among leading brands is crucial. Recent data insights reveal that not all junction boxes are created equal, with some brands offering superior performance at competitive prices. For example, brands like Brand A and Brand B have consistently topped the charts, providing robust options that balance affordability with durability. Their comprehensive testing across various environmental conditions highlights their reliability, making them favorites among electricians and contractors alike.

Moreover, the price-performance ratio can significantly impact long-term investments. A seemingly economical choice may lead to increased costs down the line due to higher failure rates or maintenance expenses. Data analysis shows that investing slightly more upfront in a well-rated junction box can save users considerable money over time. By evaluating these data-driven insights alongside real-world performance metrics, consumers can make informed decisions that not only align with their budgets but also ensure the safety and longevity of their electrical systems.

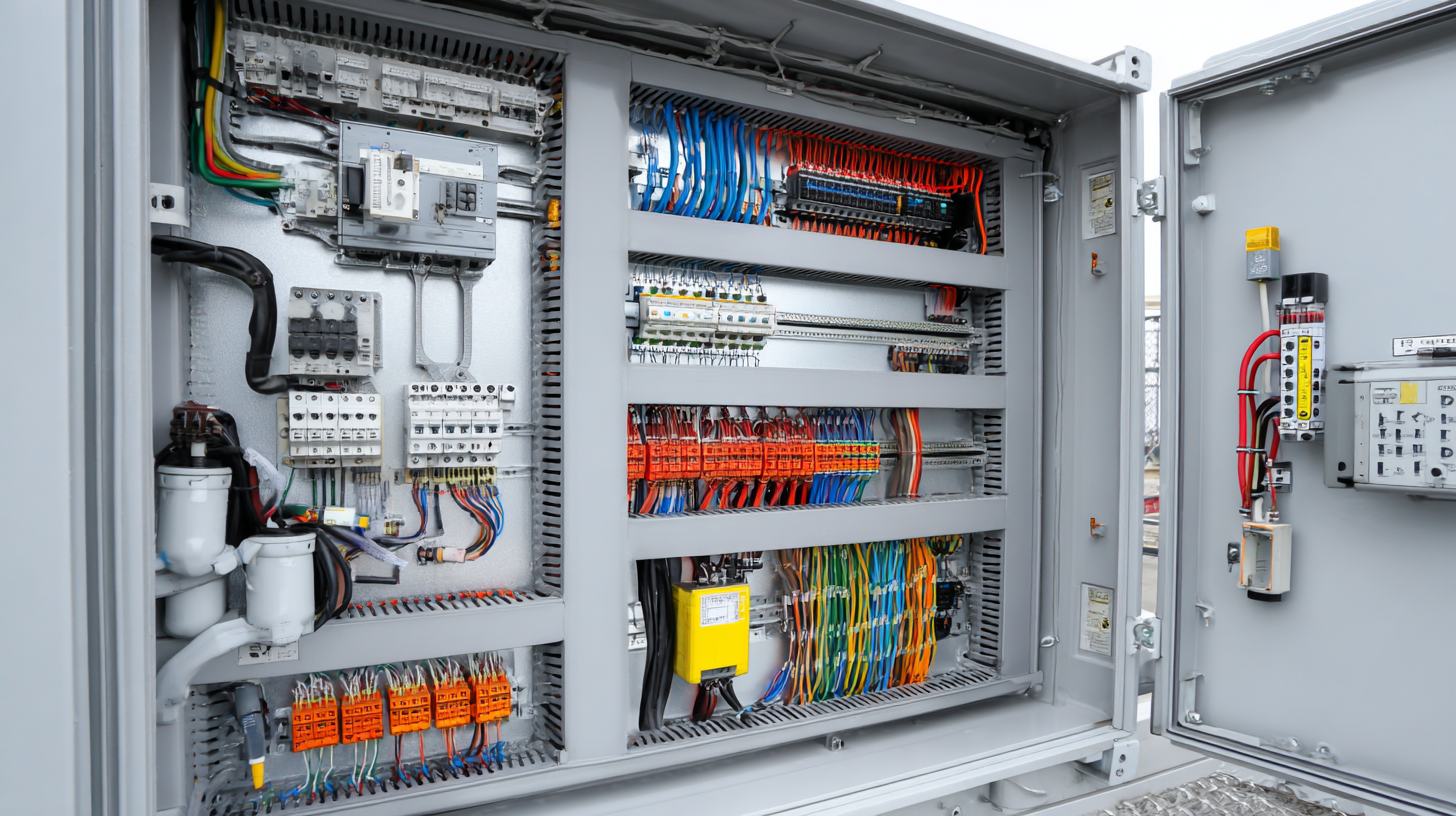

Navigating Compliance: Essential Regulations for Junction Box Manufacturers

When selecting a junction box, understanding compliance with essential regulations is crucial for manufacturers striving for safety and reliability. Junction boxes must adhere to the National Electrical Code (NEC) standards, which dictate specifications regarding material properties, installation practices, and environmental considerations. By following these regulations, manufacturers can ensure their products meet safety requirements, thus minimizing risks associated with electrical installations.

Additionally, the Underwriters Laboratories (UL) certification plays a prominent role in validating the quality and safety of junction boxes. Products that bear the UL mark have passed rigorous testing procedures, allowing consumers to trust their performance in various applications. Manufacturers should also be aware of specific industry standards, such as the IEC 60529, which relates to ingress protection ratings, guiding them in creating boxes that can withstand different environmental factors. Navigating these regulations not only aids in compliance but also enhances a manufacturer's reputation in a competitive marketplace, ultimately leading to higher consumer confidence and market success.